Facility

Arrow International is firmly decided to satisfy the total qualitative requirement of customers supplying the best of achievement of Investment casting product.

Wealth of experience and standard of excellence couple together to achieve the best quality. For that we are well equipped with all latest machine and testing equipment required in process supported by the metallurgical laboratory has a metallurgical microscope for micro structure & spectrometer for ladle and final analysis of melt.

Rockwell and Brinell Harness Tester are available for testing hardness of various components. A universal testing machine checks for tensile strength, durability properties and bend strength of internally cast test pieces. The impact testing machine determines impact strength properties.

Dye penetrate testing and radiography are used for non-destructive examination of casting, heat treatment like annealing, normalizing, solution annealing, precipitation hardening, tempering, etc are carried out in electrically heated furnace with automatic temperature controllers and records.

| Die making | Die shop in plant and reliable good source are available outside the plant to make die, zig & fixtures. |

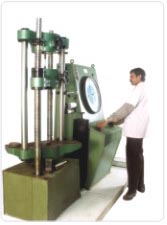

| Wax pattern shop | Centrally air-conditioned well equipped Wax Pattern Shop, with Fully Automatic and Semi-Automatic Wax Injection Presses. |

| Shell room | Centrally air-conditioned and humidity controlled Shell Room with modern equipment for building strong shells using Colloidal Silica and Ethyl Silicate slurry systems, and highly reliable Boiler-clave for de-waxing. |

| Foundry shop | Most sophisticated melting furnace to melt the molten metal with 150KG output of 150KW capacity of Induction furnace. |

| Heat treatment | As per the requirement of material heat treatment can be done in-house by the Annealing, Normalizing, Hardening and Tempering. |